Here are two basic engineering question that apply to most solar projects.

- At what tilt should the modules be mounted?

- Should the orientation be “portrait” or “landscape”?

Getting the answers right should be part of every design engineer’s Quality Assurance process. They also are important to the system owner, because in some ways the solar installer and the project owner may have opposing interests. And decisions driven by the wrong reasons can mean the difference between a project that successfully produces and meets expectations for decades, or doesn’t.

Tilt is the angle of the module to the horizon. Usually modules are installed with a tilt of 5 degrees or as much as 30 degrees.

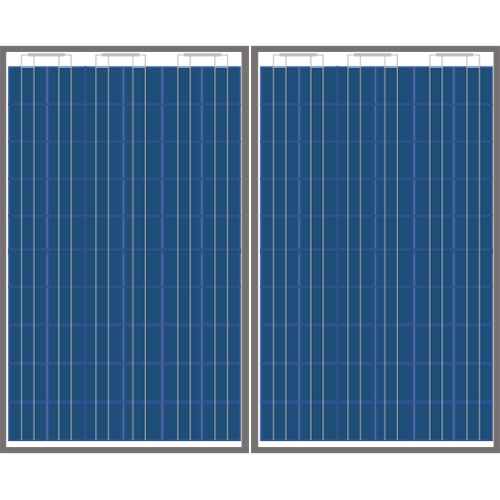

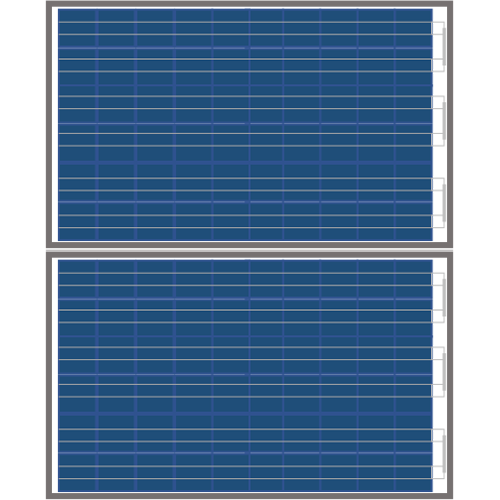

Orientation of “portrait” means the module is mounted with the short side parallel to the ground. Like a portrait painting. “Landscape” is the other way, with the long side parallel to the ground. Like you are looking at a landscape painting.

PORTRAIT ORIENTATION

LANDSCAPE ORIENTATION

- At northern latitudes where snow occurs with regularity, it is best to mount modules at a higher tilt and in landscape orientation.

- At southern latitudes where thankfully there isn’t any snow, we recommend mounting modules at a minimum tilt of 5 degrees and in portrait orientation.

- The lower the tilt, the more important it is the orientation be portrait.

- Modules should not be mounted at a zero, or flat, tilt. It is an extremely rare case where that is a good engineering idea.

MODULE TILT

Tilt is a compromise that is affected by wind, snow, allowable mounting area, strength of the ground or structure, latitude, energy cost, and the balance between desired energy cost, energy production, and season of the year. It is a true engineering decision – _problem solving and decision making when all resources are limited, including money.

Sometimes tilt is a really easy question to answer. Like if the array is going on a pitched roof: the modules should have the same tilt as the roof. Some may disagree with me on this, but I believe it is difficult to make a case based on safety, performance, and aesthetics that mounting modules with a different pitch and azimuth than the sloped roof is a good idea. There are exceptions to everything, but generally, this approach invites debris accumulation, almost never gets engineered properly for wind force on the roof attachments, and it does nothing for the argument that solar panels lack aesthetic appeal.

Other than a sloped roof, higher tilt angle usually means fewer modules can fit on the available roof or ground area. That is because the higher the tilt, the longer the shadow cast by one row of modules, and that requires more space between the rows to avoid shadowing. Take a look at the next two pictures, of a small testbed project we built 6 years ago. The rows have varied tilt (and also different power electronics, module-level optimizers, and module types throughout), and you can see how far apart the rows need to be to keep from casting a shadow on their neighbor to the north (left, in the picture). The two rows at the south (right) in the top picture are at zero tit, and could be mounted right next to each other. But we left a 6” walkway between them to allow for easier maintenance.

That’s the first reason to avoid zero-tilt arrays. While walking or kneeling on the modules probably won’t break the glass, it often results in micro-cracks in the cells and internal electrical pathways. They might not fail today, but their performance life surely will be shortened. Don’t ever let a service technician tell you it is OK to walk on the modules!

Most system owners want to produce energy and lower their cost of energy. The number of modules (the power capacity) isn’t the end goal by itself. And installing an array with zero tilt anywhere in the US or Caribbean will result in a higher cost of electricity.

Zero tilt = more difficult ongoing maintenance, troubleshooting, and repairs.

A drawback to using the optimal tilt to get the lowest energy cost is related to wind. The higher the tilt, the higher is the wind force, because the modules are sticking up higher. That means more ballast weight or more attachment points for a rooftop array, or more or deeper foundations for a ground mount.

The lower the tilt, the more snow accumulation and the longer the snow hangs around. On the zero-tilt modules, the snow doesn’t even slide off; it just turns to ice. That’s the same thing that happens when there is rain, by the way.

Besides snow performance, why is zero tilt a bad idea?

| Zero Tilt | 10º Tilt | 15º Tilt | |

|---|---|---|---|

| DC Power Capacity | 225 kW | 159 kW | 138 kW |

| Row Spacing | 0.0 ft | 1.7 ft | 2.5 ft |

| Solar Yield | 1,250 kWh/kW | 1,370 kWh/kW | 1,450 kWh/kW |

| Annual Energy | 281,250 kWh | 217,588 kWh | 200,769 kWh |

| System Cost | $ 393,750 | $ 270,000 | $ 235,385 |

| Energy Cost | $ 0.039 / kWh | $ 0.035 / kWh | $ 0.033 / kWh |

| Percent Difference | 19% | 6% | 0% |

| Roof Loading (typ) | 4 psf | 6 psf | 8 psf |

ASSUMPTIONS

Rooftop installation, 40º N latitude

Available rectangular footprint is 13,000 square feet

Additionally, when modules are mounted flat, it causes a problem with soiling and possibly the warranty on the modules.

Rain falls through the atmosphere and picks up dust from the air. All rain has a certain amount of dust and particulate matter in it. When modules are mounted at a five to 20-degree tilt, the rain runs down the glass to the bottom edge and then over the frame and to the roof or the ground. When the rain stops, there is a little sliver of water trapped at the lowest edge of the module at the depth of the frame above the glass (roughly a few millimeters). When the water evaporates, the suspended dust dries on the glass and becomes a brown, crusty deposit, again, on the lowest edge of the module surface against the frame. The higher the tilt, the thinner that sliver of dirt.

When the rain stops, the module has a puddle of water on top of the glass. That puddle is filled with dust, like before, and when the puddle evaporates, it leaves the load of dust deposited over the entire glass surface of the module.

As a result, flat-mounted modules can be clean one day, and after one rain, they look like they haven’t been washed in years. The immediate loss in productivity can be two to 3%, just from one rain event! Below is a pic of a flat array in a dusty area with a lot of industrial activity that results in extra airborne particulates, in the process of being cleaned.

MODULE ORIENTATION, LANDSCAPE OR PORTRAIT

There is little difference overall between portrait or landscape with regard to how many panels can be put on the roof or ground at a specific tilt angle. Depends more on the shape of the mounting area than anything else. Sometimes landscape will work out better and sometimes portrait is the best fit. However, the decision to mount landscape or portrait is influenced by the installation location, potential for snow and shading.

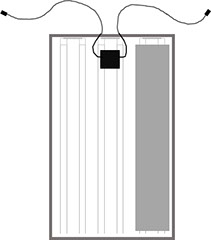

Solar modules usually are made up of 60 or 72 or 96 individual solar cells. These are connected within each module in series circuits of 20 or 24 or more, and then those series circuits are connected in series so that each module’s voltage is the sum of all the cells. For example, cells produce around 0.5 V, and for a module that has 60 cells, that results in a module voltage or 30 V.

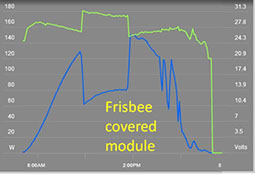

The green line in the production curve trace is module voltage, and the blue line is module current.

Now let’s revisit the shading design and ignore the situation where a leaf or frisbee randomly covers one cell. Let’s look at what happens with modules in portrait or landscape, when something causes shading. This can be snow, or as in the next photograph, when someone installs the fence too close to the array!

Modules are built with a wider border on the short side. That means when the modules are dirty on the bottom edge (not zero tilt) then there can be more dirt accumulated before the cells start to get shaded. While I do not know this for a fact, I believe this is because manufacturers intended modules to be mounted in portrait to provide better performance with dirt crust shading on the bottom edge.